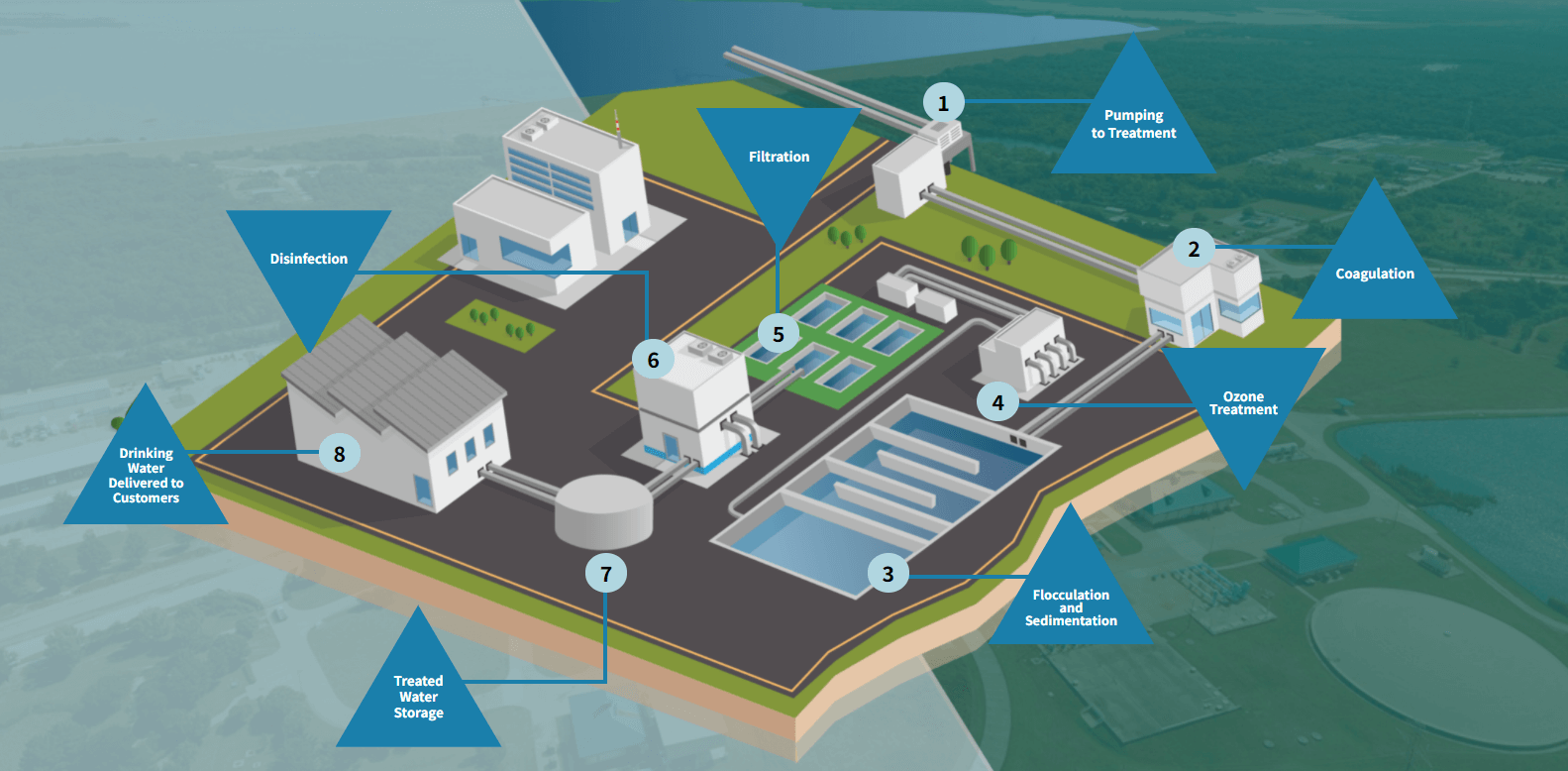

Before a drop of our water ever comes out of your faucet, it undergoes a rigorous, eight-step process at one of our two plants. We use state-of-the-art technology at every stage and test our water to ensure that it meets all water quality requirements.

Click on each component below to learn more about UTRWD's water treatment process:

Our plants, pumps and pipelines have the ability to treat up to 90 million gallons of water every day (MGD): 70 MGD at Tom Taylor Plant and 24 MGD at Tom Harpool Plant (which has also been designed for expansion up to 24 MGD). UTRWD treats and delivers an average of 24 million gallons of water per day, or 9 billion gallons per year. The amount of water we treat fluctuates with the seasons. During the winter, UTRWD treats on average 15 million gallons per day, reaching above 50 MGD during the summer. During 2018, UTRWD treated 65 million gallons in one day--an all-time high.

Our Tom Taylor Water Treatment Plant in Lewisville uses ozone technology primarily to improve taste and odor, but also as a disinfectant. In the future, we expect to include ozone technology at the Tom Harpool Water Treatment Plant. We have received both the Best Tasting Water in the North Texas region and statewide awards numerous times for our Taylor Water Treatment Plant, as well as Outstanding Large Membrane Plant Award for our Harpool Water Treatment Plant.

Delivering Your Water

Once it is treated, Upper Trinity Regional Water District (UTRWD) uses over 103 miles of pipeline to deliver its water to over 20 Members and Customers cities, towns and utilities.

Our Pipeline System Includes:- 2 pump stations (Stone Hill and Temple Dane)

- 1 elevated storage tank/booster station

- 3 water storage facilities

UTRWD's transmission pipelines extend from Justin to Celina and from Castle Hills to Sanger. Our Stone Hill Pump Station includes two ground storage tanks and a pump station. It delivers water to customers in the western portion of UTRWD's service area. The Temple Dane joint pump station and 1 million gallon storage facility is operated in partnership with Mustang Special Utility District and delivers to our northern service area. The elevated storage tank and booster pump station is used to increase pressure in the system when demand is particularly high.